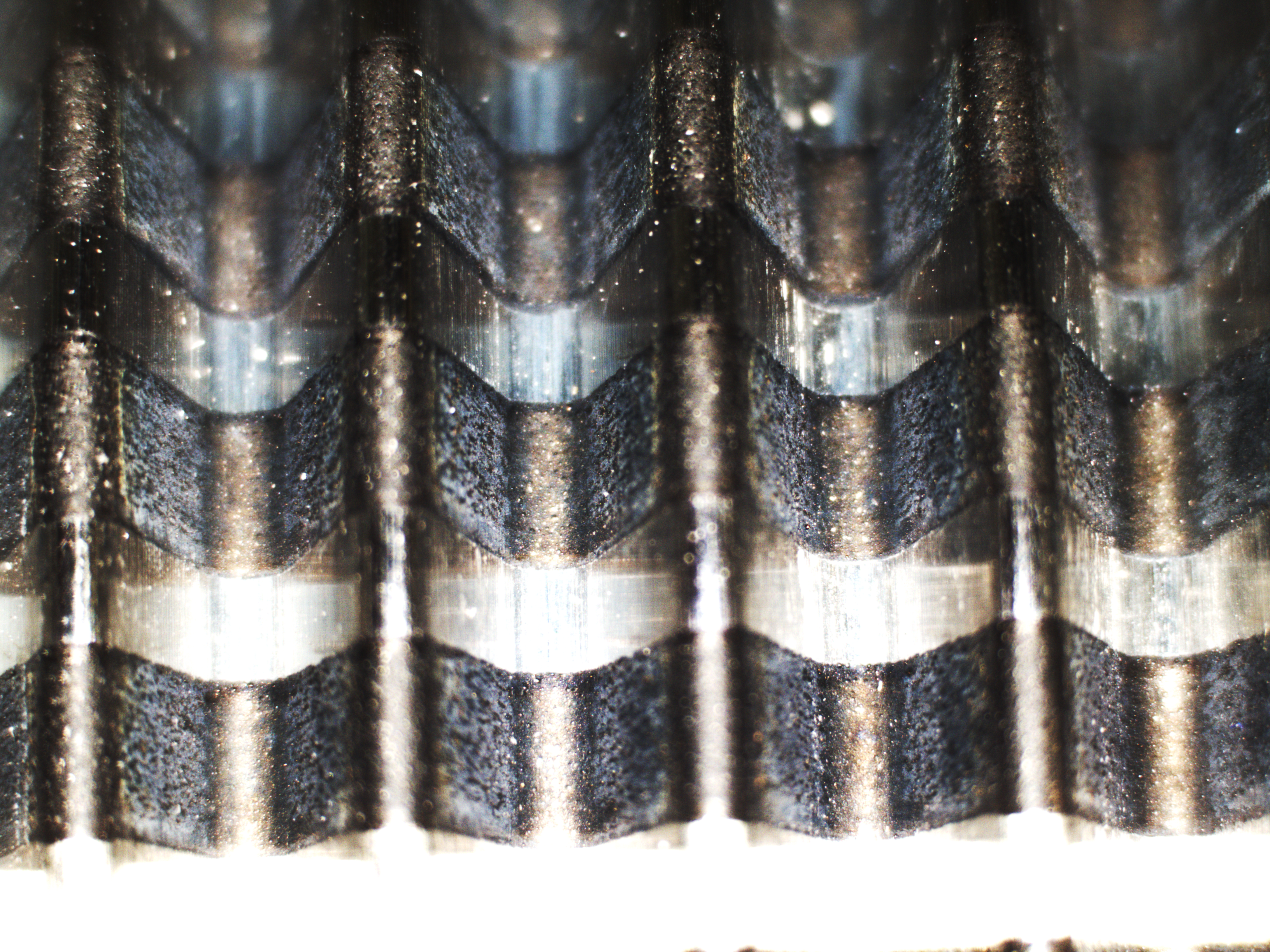

GripTec® weld

GripTec® Weld is a micro welding process that infuses a combination of metals and or engineered aggregate on the micron µ scale to achieve a desired friction coefficient on the targeted surface. Our welding process is near limitless and we apply our technology to give the target component the desired friction coefficient that optimizes the safest most aggressive gripping force possible and in some cases a more durable surface coat than the base material. US Patent 8,931,156

Belt slip is a very common issue on supercharged components. In fact some units cranking out as much as 14-16 psi can take up to 200hp to drive. Often the drive systems are plagued with slippage issues and engine builders find themselves moving to noisy cog systems, where belts have shorter life spans, are difficult to find at just any parts store and create more heat through the frictional movement of the cogs shortening bearing life.

Belt slip isn't always noticeable. Often belt slip is noticed when the system squeals, squeaks or boost falls off. Did you know that naturally the belt can slip a very small percentage even on NA vehicles, one major factor to belts wearing. Belt wrap does play a key factor in minimizing belt movement but when it comes to driving a supercharger is hard to fully eliminate with just surface contact. Systems running 3.4 upper pulleys can see as much as a 1.5 psi gain when matching size for size pulleys.

Whether you are running 6 psi or 20+ psi you are slipping if you are not running GripTec®